What is Foundation?

The foundation is an important part of the structure. It is defined as the part of the structure that distributes the load from the structure built on it as well as its weight over a large area of soil in such a way that the amount does not exceed the ultimate bearing capacity of the soil and the overall settlement remains within a tolerable limit. The foundation is the part of a structure that supports the structure. The foundation bed is the solid ground on which it rests.

|

Types Of Foundations |

Why a Foundation is Provided

The foundation should achieve the following goals:

1.Distribute the structure's weight over a large area of soil.

2.Avoid unbalanced settlement.

3.Prevent the structure from moving to the side.

4.Boost structural stability.

Types of Foundation and their Uses

All foundations are classified into two types: shallow foundations and deep foundations. Shallow and Deep Foundations refer to the depth of the soil in which they are installed. If the width of the foundation is greater than the depth, it is referred to as a "Shallow Foundation." When the width of the foundation is less than the depth of the foundation, it is referred to as a "Deep Foundation." However, deep foundation and shallow foundation can be distinguished as shown in the chart below.

Shallow Foundations:

It is the most common type of foundation for lightweight structures since the shallow foundation depth is minimal and it is affordable. Below, a number of shallow foundation types are covered.

|

Shallow Foundations |

Wall Footing:

Wall footing is also known as continuous footing This type is used to distribute loads from structural or non-structural load-bearing walls to the ground so that the soil's load-bearing limit is not exceeded. It runs in the same direction as the wall. The foundation of a wall is typically 2-3 times the width of the wall.

For individual columns, walls, and bridge piers when the bearing soil layer is less than 3 meters (10 feet) from the ground surface, spread footings and wall footings are employed. To support the weight of the structure over its base area, the soil bearing capacity must be adequate.

These shouldn't be utilized on soils where there's a chance that water will seep through the bearing layer and cause scour or liquefaction.

Isolated Spread Footing:

The most common type of foundation used in building construction is an isolated footing or individual footing. This foundation, also known as a pad foundation, is designed for a single column.

Individual footings are square or rectangle in shape and are used when loads from the structure are carried by the columns. The size is determined by the load on the column and the safe bearing capacity of the soil.

ISOLATED FOOTING |

Rectangular isolated footings are used when the foundation experiences moments caused by eccentric loads or horizontal forces.

As an example, If a column has a vertical load of 200 kN and a safe bearing capacity of 100 kN/m2, the required footing area is 200/100 = 2m2. As a result, the length and width of a square footing will be 1.414 m x 1.414 m.

Combined Footing:

Combined footing is constructed when two or more columns are close enough and their isolated footings overlap each other. It is a combination of isolated footings, but their structural design differs.

The shape of this footing is a rectangle and is used when loads from the structure is carried by the columns.

- The columns are positioned closely one to another.

- when the footing would cross the property line or become eccentric and the column was close to the property line.

- The footing's dimensions on one side are limited to a certain lower value.

Strap Footing:

Strap footings and combined footings are both types of footings. The reasons for considering or selecting strap footing are the same as for the combined one.

The foundation beneath the columns is built individually and connected by a strap beam in strap footing. When the edge of the footing cannot be extended beyond the property line, the exterior footing is connected to the interior footing by a strap beam.

|

| STRAP FOOTING |

Raft or Mat Foundation:

Raft or mat foundations are the types of foundations used throughout the entire building to withstand the large structural loads from the columns and walls.

|

RAFT OR MAT FOUNDATIONS |

Mat foundations are used for column and wall foundations where the loads from the structure on the columns and walls are extremely high. This is used to prevent differential settlement of individual footings, and is thus designed as a single mat (or combined footing) of all the structure's load-bearing elements.

Raft foundations are cost-effective when:

- Because the soil is weak, the load must be distributed over a large area.

- The building has a basement.

- The columns are close together.

- Other foundation types are not feasible.

- Differential settlement must be avoided.

Deep Foundations:

The types of deep foundations are as follows.

|

PILE FOUNDATION |

Utilization of Pile Foundation

The subject of when pile foundations are appropriate arises frequently. Here are several scenarios in which adopting a pile foundation system can be advantageous.

- Heavy and irregular loads are imposed by the superstructure.

- Other types of foundations are either too expensive or impractical.

- when the soil is compressible at shallow depths.

- when scouring is a possibility since it is close to a riverbed, the beach, etc.

- when a deep drainage system or canal is located close to the structure.

- when unfavorable soil conditions prevent soil extraction from reaching the specified depth.

- The greatest option is foundation pilings when the groundwater table is high.

Factors Influencing Pile Foundation Selection

The following factors influence pile foundation selection:

Soil characteristics

Structure-borne loads

Load Characteristics

The number of piles that will be used

Construction expenses

Pile Foundation Types

Depending on the factors mentioned above, piles are generally classified into three types.

End bearing piles

Friction bearing piles

Combination of end bearing and friction bearing piles

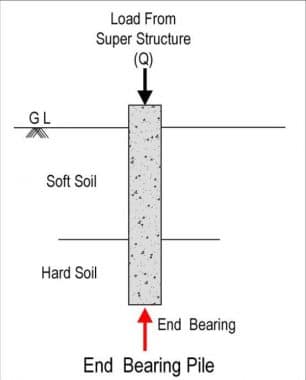

End Bearing Pile Foundation:

End bearing piles, also known as point bearing piles, are used when the depth of hard soil strata or bedrock at the site is reasonable. The length of the pile to be used can be easily calculated using bedrock depth from soil exploration borehole records.

Loads from structures are directly transferred to hard soil in this case via the bearing action of the pile bottom tip, and skin friction is not required to resist loads. In such cases, the cost of pile construction is optimal. The ultimate bearing capacity of a pile or pile group is determined by the bearing capacity of the bedrock or hard strata. The number of piles to be used in this case is determined by the loads from the structure and the individual capacity of the piles. In this instance,

QU = QP

Where QU is the pile foundation's ultimate load capacity and QP is the load carried by the end bearing pile or pile group. Piles should be extended a few metres into the hard soil strata if hard bedrock is not available at a reasonable depth and a fairly compacted hard strata of soil exists.

Friction Pile Foundation:

Friction piles withstand structural loads due to skin friction with the soil. When a hard stratum is available at a great depth and the construction of an end bearing pile becomes uneconomical, this type of pile foundation is used. The number of piles in a group is then chosen to resist the load from the structure via skin friction. This type of pile foundation also resists loads due to end bearing, but because its value is small, it is ignored in calculations.

|

FRICTION BEARING PILE |

The length of the friction pile to be chosen in this case is determined by the shear strength of the soil, loads from structures, and pile size. The capacity of an individual pile is calculated using the skin friction resistance provided by the pile length chosen. The maximum length of this pile should be used in consideration of economy. Individual pile capacity can be used to calculate the number of piles needed in a group. In this instance,

QU = QS

Where QU is the pile foundation's ultimate load capacity and QS is the load carried by the friction pile or pile group. The load is transferred to the soil via friction in sandy soil and adhesion in clayey soil. Loose sand and soft clays may not have enough skin friction or adhesion resistance to withstand heavy loads from structures.

Combined End Bearing and Friction Pile Foundation:

This pile foundation is commonly used in construction. The benefit of using this pile is that it can withstand structural loads through end bearing and friction resistance. This pile has a high pile capacity and is cost effective. When soil exploration results show hard bedrock or fairly compacted soils at a reasonable depth and soil above bed rock supports skin friction resistance, this pile is used.

QU = QS + QP

Caisson Foundation:

Drilled shafts, also known as caissons, are a type of deep foundation with an action similar to pile foundations discussed previously, but they are high capacity cast-in-situ foundations. It resists structural loads through shaft resistance, toe resistance, or a combination of the two. An auger is used to construct drilled shafts or caissons.

Drilled shafts can carry heavier column loads than pile foundations. It is used when the depth of hard strata beneath ground level is between 10m and 100m (25 feet to 300 feet).

When deep deposits of soft clays and loose, water-bearing granular soils exist, drilled shafts or caisson foundations are not suitable. It is also unsuitable for soils with difficult to stabilize caving formations, boulder soils, or artesian aquifers.

Types of caisson foundation

Open caissons

Pneumatic caisson

Floating caisson

- Cassion is used to construct bridge piers because it is almost entirely submerged.

- It's also used for the pump house, which is subjected to tremendous vertical and horizontal forces.

- It is also used for multi-story buildings. However, it is sometimes used.

- Pneumatic cassion is used in railway bridges, garbage pits, water supply and sewage facilities, and other applications.

- Caissons allow access to a deep shaft or tunnel.

- Caissons have also been used to install hydraulic electors, which have a single-stage ram installed below ground level.

- The bottom is excavated and the concrete is poured in dry conditions.

- Because there is access to the caisson's bottom, obstructions such as boulders or logs can be easily removed.

- The verticality of a pneumatic caisson is easier to check and control than the verticality of an open caisson.

- Because the concrete is dry, good and dependable quality work can be obtained.

- In-situ tests in the working chamber can easily determine soil bearing capacity.

- Construction costs a lot of money. When open caissons are not possible, pneumatic caissons are used.

- The penetration depth below the water level is limited to 35 m.

- There are numerous inconveniences caused to workers who work under duress. Workers may contract caisson disease. As a result, proper health controls for workers are required.

- A large amount of manual labour is required in pneumatic caissons, which raises the cost.

- The high level of expertise required for sinking.

0 Comments